TRIO TECHNOLOGY

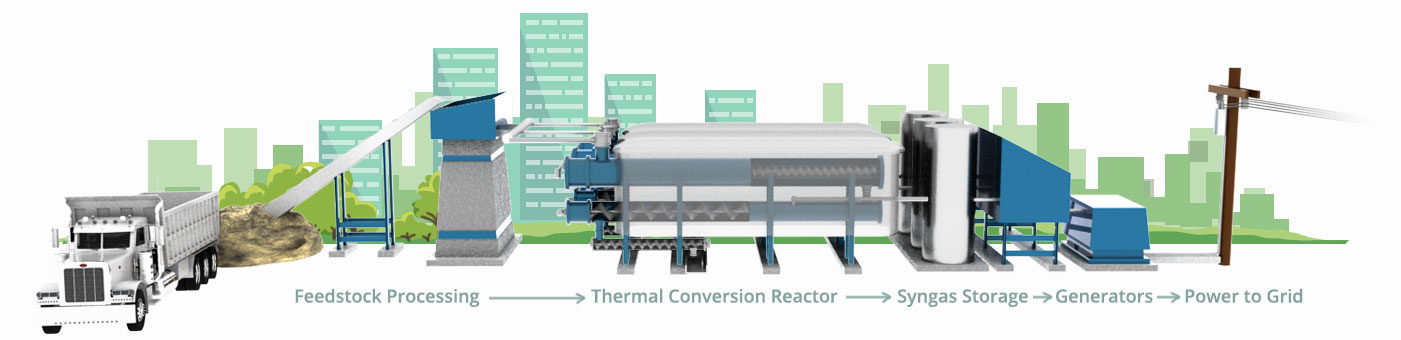

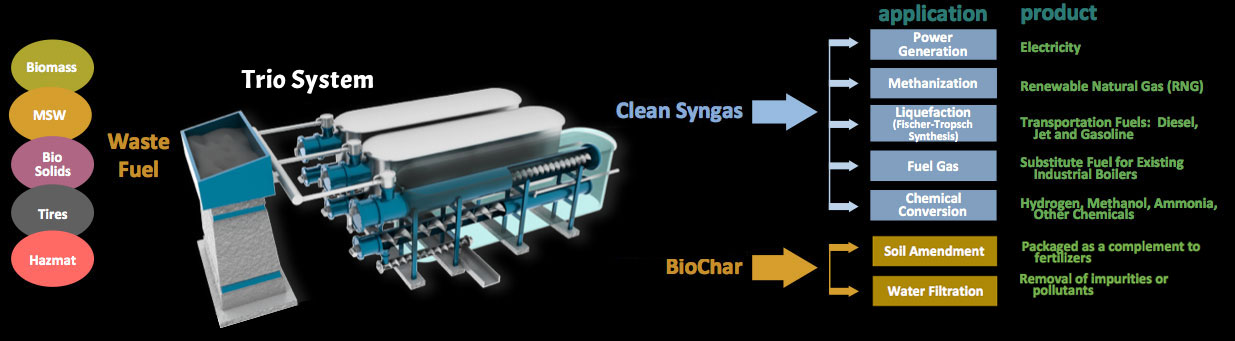

Our low emissions single 1MW closed-loop system converts up to 2 tons of waste per hour, generating continuous net power for inside-the-fence solutions or interconnected to local power providers.

Trio Vortex®

and volume

Trio Reactor®

Trio SynGas®

Trio Design Heritage

Our system is rooted in the design and development efforts for the US Military by the major defense contractor Scientific Applications International Corporation (SAIC). From 1985 to 2015, SAIC made significant investment in the program to ensure 24/7 autonomous power availability in forward operation bases in almost any condition. In 2018 Trio acquired the intellectual property and exclusives rights for this technology for use in commercial markets. The first unit SAIC developed was a successful proof of concept which served as a catalyst for the next generation SAIC design producing 1MW of power per unit.

The proof of concept unit is currently housed and operationally ready at a Trio leased facility in Brawley, California where the unit was thoroughly tested and approved for California Environmental Quality Act (CEQA) operation.

Output can be optimized by flow rate & temperature

How it works

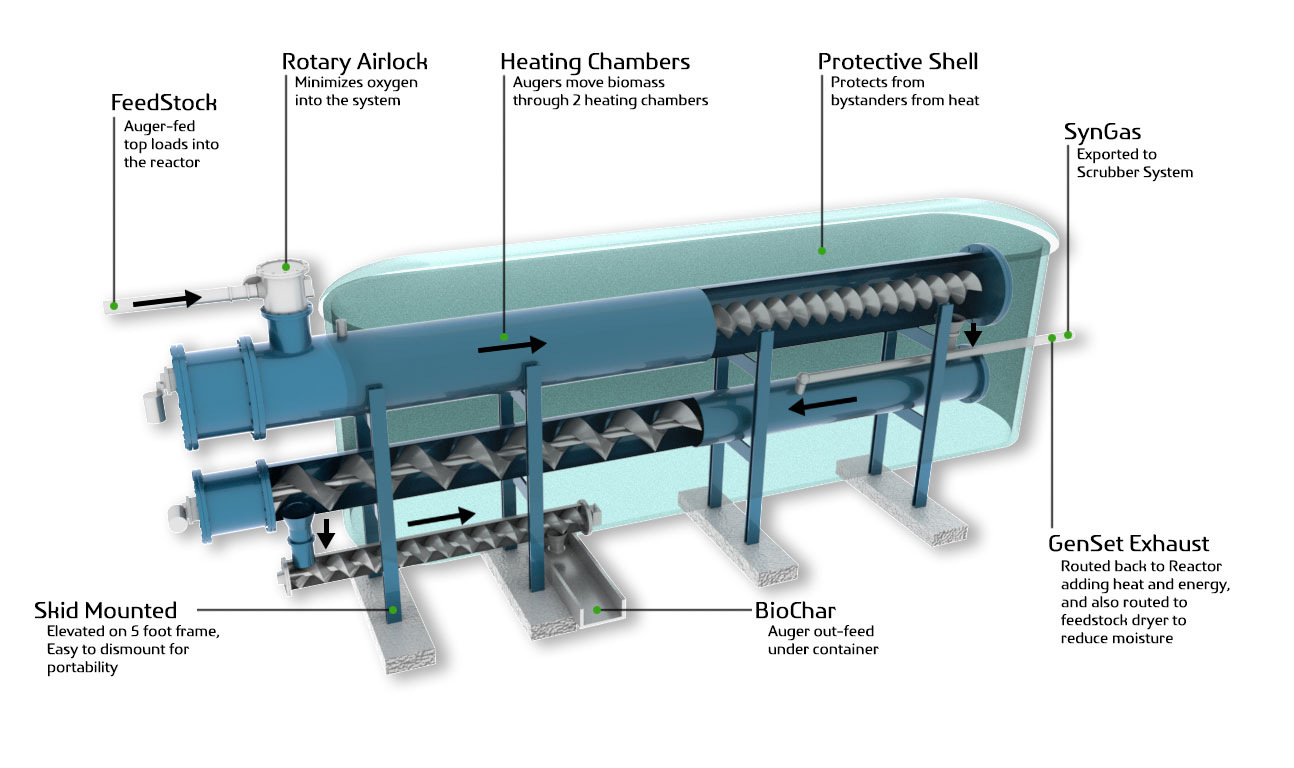

The Trio System utilizes a technology called fast pyrolysis, a proven and scalable thermal conversion technology. Fast pyrolysis is a rapid thermal decomposition of carbonaceous organic matter in the absence of oxygen. This process occurs at low pressure, moderate temperatures and over a very short period of time. There are three products as result; syngas, biochar, and pyrolysis oil. The output optimization of these products is regulated by varying the temperatures (1200°F to 1750°F) and the rate of material conversion.

The Pyrolysis technique is a sustainable solution that is economically profitable and minimizes environmental concerns in the areas of waste minimization, carbon sequestration, soil amendment, energy/heat supply, value added chemicals and development of rural areas.

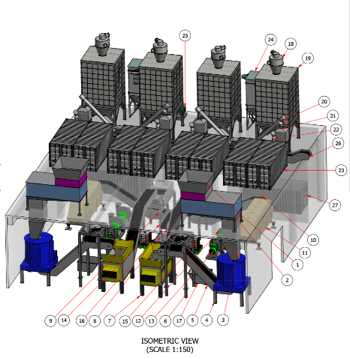

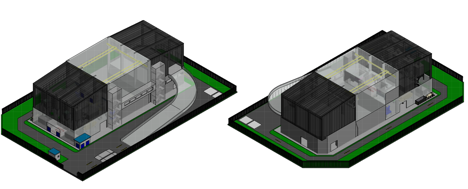

1MW Unit Design

Designed by SAIC and refined by Trio, the upgraded 1MW fast-pyrolysis reactor is an enhancement based on the principles of previously developed models. The component details of this design are proprietary to Trio, and there are no other configurations in the commercial market which equal its capabilities.

Unit manufacturing is currently performed in the USA with proven vendors uniquely qualified to deliver our state-of-the-art system.

Material Preprocessing: The Trio Vortex®

Biomass or feedstock needs to be processed prior to entering the thermal reactor. Trio will configure your preprocessing system to optimize for the type of feedstock and the expected mass participation. For example, wood mass may simply be shredded, metal removed, and moisture reduced. On the other hand, municipal sanitary waste streams may requires separation processing to ensure only the right materials are processed.

Thermo-Chemical Conversion: The Trio Reactor®

Microgrid Integration Capability

The Trio System is highly flexible and standards compliant, meeting full range of Microgrid compatibility standards. 250kW, 2MW, and 4MW industrial electrical standard versions can link into “rings”, providing up to 16MW total power. A network of software, intelligent power rectifiers, transformers, routers, and sensors balances power between various sources; grid, other renewable units, generation, storage, and load. Our system controls and blends power sources operating in grid neutral or islanding and is responsive to varying inputs and loads. Our system can integrate single or multiple generator systems, as well as renewable power sources such as wind and solar.

Trio technology synchronizes with all grid implementation, including to DC, DC to DC, and DC to AC, We also provide “Blinkless” UPS Capability.

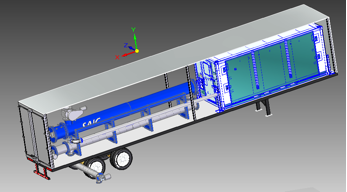

Portable, Modular and Scalable

The Trio thermal conversion system is modular in design, customizable and scalable to each applicable project need. We utilize standardized shipping containers, so the Trio System is easy to install and ship worldwide.

Mobile Units:

Multiple 53-foot trailers can be configured side-by-side, as an “L,” “V” or straight line, conforming to site requirements. If more capability is needed in a phased approach, the next set of trailers can be shaped in any direction, or even be moved off-site if proximate. These self-sustaining units are energy self-reliant.

Fixed Installation: